What are Corrugated Panels?

Corrugated metal roofing is a metal sheet that is rolled and formed into metal panels. These panels are then attached to the roof with screws. Corrugated metal is an exposed fastener panel, meaning that each fastener is visible on the panel’s surface.

Roofing Applications

2.5″ corrugated panels are a popular choice for post-frame buildings such as horse barns, riding arenas, machine storages, sheds, and most other buildings for agricultural use. Our quality steel is made in the USA and is by far the most efficient and economical choice for most low-rise building applications.

Modern corrugated metal roofing panels are usually made out of galvanized steel. For roofing applications, a minimum slope of 3:12 is recommended. Primarily, they are implemented as metal roofing or wall systems composed of corrugated panels held in place by exposed screws / fasteners color-matched to the paint color of the metal panels. Often caulking is used at the overlap in between the panels for water tightness.

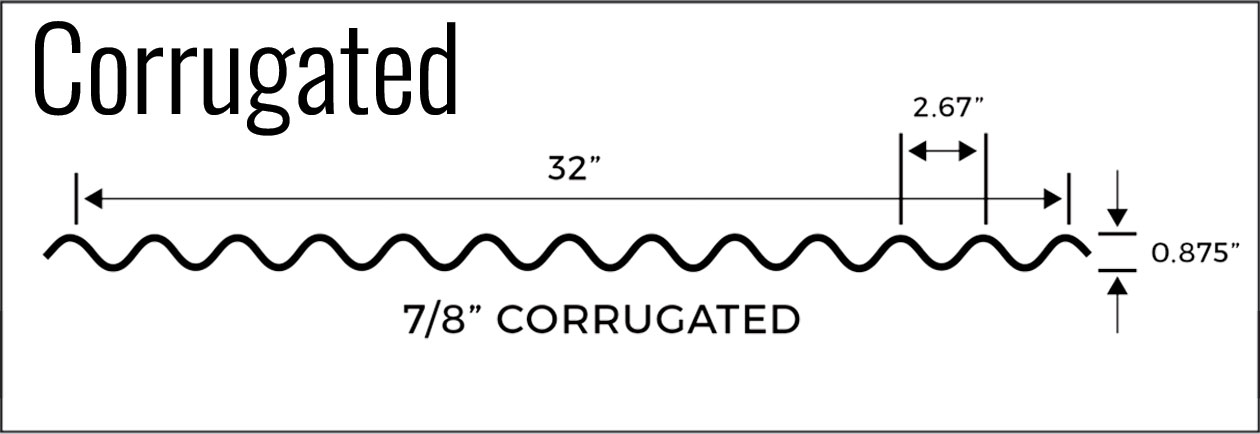

Corrugated panels are available in the “⅞” Corrugated” style. It is 32” of coverage, with a 0.875” rib height

What You Need To Know About Corrugated Panels.

- We stock 12’ sections in 26-gauge, galvalume & bare steel (will rust)

- Can order in whatever is needed with a 2-4 week lead-time

- Shortest length available is 30”

- 26-gauge or 24-gauge

- Can make trim to fit with the corrugated style

- Materials provided by 3rd party

Side Lap Procedure

Please see side lap detail. Pay careful attention that the uneven rib is over lapped by the even rib as shown in the side lap detail.

End Lap Procedure

When long panels are required. Tri-State Metal Roofing Supply recommends the customer to consider lapping the panels a minimum of 16” to insure proper drainage. Two strips of butyl sealant tape should be used at the end lap and fastened on the uphill side of the strips of butyl sealant tape.

Eave Detail Procedure

Tri-State Metal Roofing Supply recommends the use of an eave flashing with butyl sealant tape above and below the closure strip (inside) which will go between the underside of the roofing panel and on the top side of the flashing to avoid water infiltration.

Ridge Detail Procedure

The appropriate ridge cap is placed on top of the solid closure strips (outside) with butyl sealant tape above and below the closure fastened through each rib at 9” on center. A vented closure strip can also be used to provide adequate air flow in and out of your attic. A longer screw (2”‐2.5”) is recommended to be used to fasten the ridge. Each section of ridge cap needs to be overlapped a minimum of 12 inches.

Fasteners

Metal to Wood application‐ Tuff‐Rib panels should be fastened by a minimum #9 x 1.5” wood grip. Metal to Metal application‐ Tuff‐Rib panels should be fastened by a minimum #12 x 1” Tek screw

Siding Applications

Tuff‐Rib panels used as siding are side lapped the same as in the roofing application. It is best to start a siding sheet at a large opening (i.e. sliding door, window, door etc.) so that the panels are square. Butyl sealant tape is not required for side lap application. However, butyl sealant tape is recommended where any closures are required.

Trimming And Cutting Steel Panels

Whether cutting with the profile (length‐wise) or across the profile (width‐wise), it is best to use a steel cutting blade or an abrasive, self consuming (carboundum) blade with an electric saw, hand tin snips or a nibbler. It is very important to cut panels one at a time with the finished side or panel facing down on wood blocks. Care should be taken to ensure that the hot metal particles and filings from the cutting do not become embedded in the panel.

Notes

Filings from screw cuttings must be cleaned off the panels after screws have been applied through the panel to avoid rust marks or “bleeding” on the panels. Store only in a dry place. Stack flat on blocks or racks to protect bottom panels. Failure to comply with the above procedures relieves Tri-State Metal Roofing Supply responsibility of damage to or deterioration of the finish and voids any paint or finish warranty.

Manufacturer Direct Pricing

Open to The Public

Ontime Production Guarantee

Delivery Services Available

Fast Free Estimates

Quality American Made Materials

100% American Made Steel Roofing Supplies

Our Clients Love Us

Locations

Ogden, Utah

- 770 W River Park Dr.

Riverdale UT 84405 - Phone: 801-689-0989

- riverdalesales@tsmetalsupply.com

Payson, Utah

- 1688 West American Way

Payson, UT 84651 - Phone: 385-297-7663

- paysonsales@tsmetalsupply.com

St. George, Utah

- 3113 E. Deseret Drive

St. George, UT 84790 - Phone: 435-627-1829

- stgsales@tsmetalsupply.com